Introduction of VENEZINA

Introduction of VENEZINA

02.17.2023

A sense of optimistic is central to our brand expression, and that sensibility leads to imaginative

Focus on R&D

Focus on R&D

10.20.2022

The General Guidelines

. Getting close to the actual needs of the market and the potential demand

Development Process

Development Process

10.20.2022

VENEZINA has been committed to constant innovation in the lighting field since 1995. we now owns com

Introduction of VENEZINA

Introduction of VENEZINA

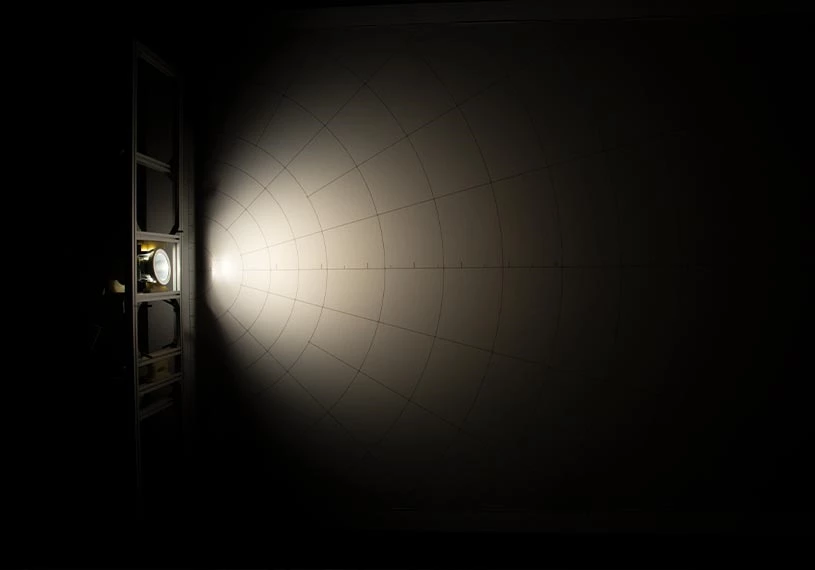

.jpg.webp) Lighting solution and lumination calculation

Lighting solution and lumination calculation

Focus on R&D

Focus on R&D

Development Process

Development Process